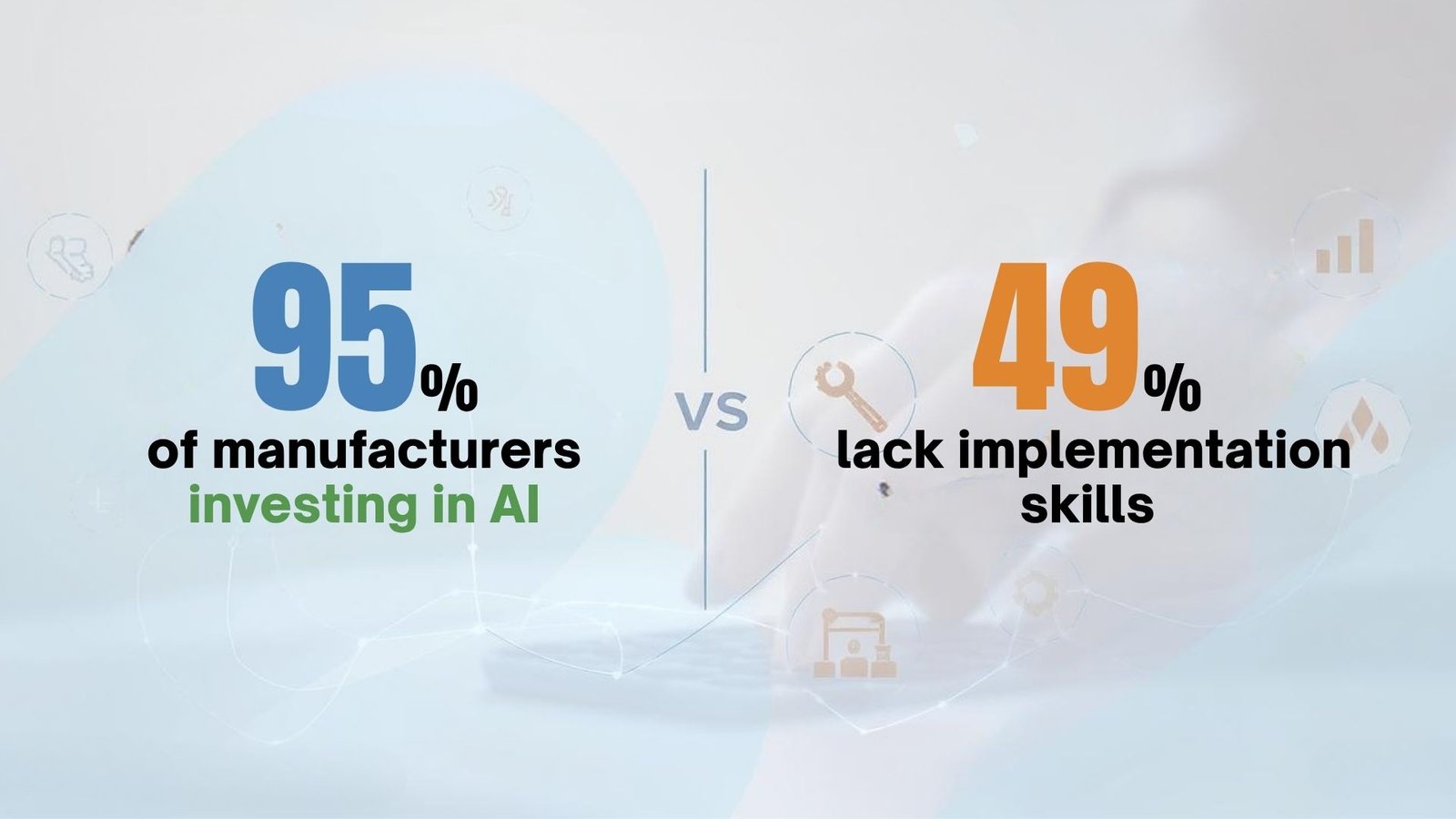

95% of Manufacturers Are Investing in AI

But 49% Lack Implementation Skills: Here’s How to Bridge the Gap

Yesterday’s Rockwell Automation study sent shockwaves through the manufacturing world: 95% of manufacturers plan to invest in AI/ML over the next five years. But buried in the same report was a sobering reality check – 49% admit they lack the implementation skills to make these investments successful.

This represents a $20.8 billion opportunity by 2028, with a compound annual growth rate of 45.6%. Yet, the gap between investment enthusiasm and implementation capability threatens to derail this digital transformation for nearly half of all manufacturers.

Key Findings from the Study

- • 81% say external pressures are accelerating digital transformation

- • 95% have invested or plan to invest in AI/ML within 5 years

- • 49% plan to use AI for cybersecurity in 2025 (up from 40% in 2024)

- • 48% plan to repurpose or hire additional workers due to smart manufacturing

The AI Investment Landscape: Massive Opportunity, Massive Challenge

Market Size by 2028

Expected AI in manufacturing market value with 45.6% CAGR

Investment Rate

Manufacturers investing in AI/ML over next 5 years

What’s Driving the Investment Rush?

Supply Chain Disruptions

Global supply chain volatility drives need for predictive analytics and intelligent planning

Labor Shortages

41% using AI to close skills gaps and address workforce challenges

Competitive Pressure

Need for operational efficiency and data-driven decision making

In the Asia-Pacific region, including our key markets of Sri Lanka and Australia, manufacturers are particularly focused on leveraging AI for quality control (50% planning implementation) and predictive maintenance, recognizing the critical role of technology in maintaining competitive advantage.

The Implementation Reality Check

While investment enthusiasm runs high, the path from AI investment to successful implementation is fraught with challenges that many manufacturers underestimate.

The Skills Gap Crisis

Lack implementation expertise

Up from just 10% who considered AI skills important last year

Struggle with data integration

Cannot effectively connect disparate systems

Common Failure Points

Lack of Unified Data Strategy

AI systems require high-quality, integrated data. Many manufacturers operate with data silos that prevent effective AI implementation.

Disconnected System Architectures

Legacy ERP, isolated BI tools, and separate planning systems create barriers to AI integration.

Insufficient Change Management

Technical implementation without proper training and process adaptation leads to user resistance and project failure.

The bottom line: Most manufacturers are building AI on shaky foundations, hoping disconnected systems will somehow work together seamlessly.

The Connected Systems Solution

At PentagonIT, we’ve identified the key to successful AI implementation: connected ecosystems that break down barriers between systems and create a unified foundation for intelligent automation.

ERP Foundation

Axpert Low-Code Platform

- • Unified data architecture

- • Rapid customization capabilities

- • Future-proof scalability

- • 50% faster development

Intelligence Layer

Qlik Business Intelligence

- • AI-ready data visualization

- • Real-time analytics

- • Predictive capabilities

- • Self-service insights

Smart Planning

Opcenter APS

- • Intelligent optimization

- • Dynamic scheduling

- • Resource allocation

- • Real-time adaptation

Integration Benefits

Faster Deployment

Data Integration

AI Success Rate

Regional Success Stories

Sri Lankan Manufacturing

Textile Industry Transformation

Leading apparel manufacturer achieved 35% reduction in planning time and 28% improvement in on-time delivery through integrated ERP-APS solution.

Food Processing Optimization

Major food processor eliminated data silos, enabling real-time quality monitoring and 15% waste reduction.

Australian Manufacturing

Mining Equipment Excellence

Mining equipment manufacturer deployed connected systems, resulting in 40% faster order processing and improved inventory accuracy.

Agricultural Technology Innovation

AgTech company leveraged integrated BI and planning systems to optimize production schedules and reduce costs by 22%.

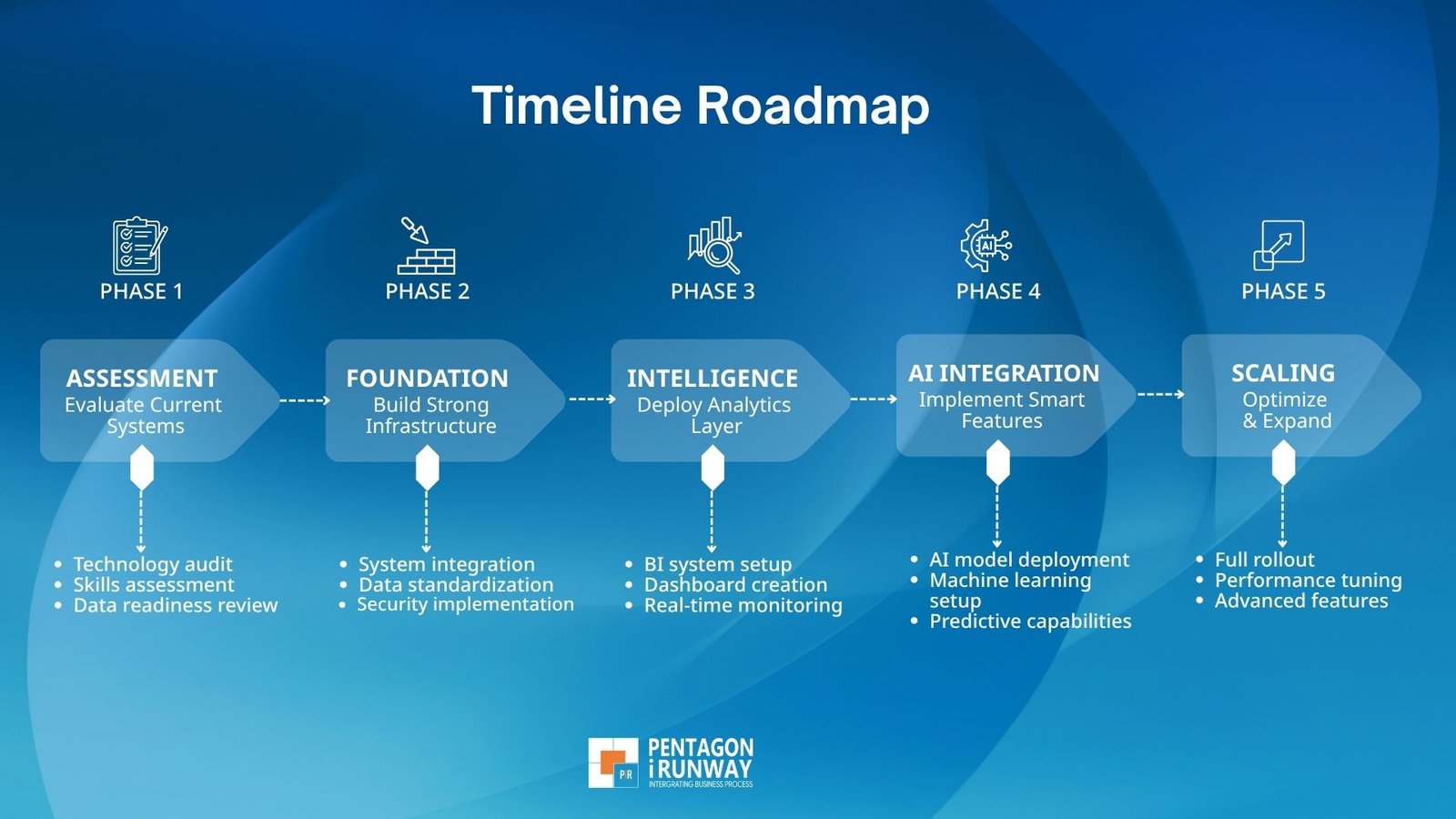

Practical Implementation Roadmap

Assessment Phase

Evaluate existing ERP, BI, and planning systems

Assess data quality, integration, and accessibility

Identify training and resource requirements

Foundation Building

Implement Axpert low-code platform

Standardize and centralize data sources

Develop internal capabilities and expertise

Intelligence Layer Addition

Deploy Qlik for advanced analytics

Create role-specific visualizations

Enable self-service data insights

AI Integration

Start with high-impact, low-risk applications

Phase implementation across departments

Track KPIs and optimize performance

Scaling and Optimization

Expand AI across all operations

Refine algorithms and processes

Implement next-generation AI features

Overcoming Common Challenges

Challenge: Limited AI Expertise

Internal teams lack experience with AI implementation and integration.

PentagonIT Solution:

Partner with our implementation specialists who have 10+ years of experience. We provide comprehensive training and knowledge transfer throughout the project.

Challenge: Budget Constraints

High upfront costs and unclear ROI make investment decisions difficult.

PentagonIT Solution:

Phased implementation approach with clear ROI milestones. Start with high-impact areas and expand gradually based on proven results.

Challenge: Change Resistance

Employees fear job displacement and resist new technology adoption.

PentagonIT Solution:

Comprehensive change management program focusing on upskilling and new role opportunities. 48% of manufacturers report hiring additional workers due to smart manufacturing.

Challenge: Data Quality Issues

Poor data quality and integration prevent effective AI implementation.

PentagonIT Solution:

Integrated system architecture ensures data quality from source. Our three-pillar approach creates a single source of truth for all AI applications.

Future Outlook: The Evolution of Smart Manufacturing

As we look ahead, several key trends will shape the future of AI in manufacturing, creating new opportunities for companies that build the right foundation today.

Autonomous Manufacturing

Self-optimizing production systems that adapt in real-time to changing conditions, enabled by advanced AI and machine learning algorithms.

Sustainability Integration

AI-driven optimization for carbon footprint reduction, waste minimization, and energy efficiency across the entire manufacturing process.

Hyper-Connected Supply Chains

End-to-end visibility and predictive analytics across global supply networks, enabling proactive risk management and optimization.

Workforce Transformation

New roles focused on AI management, data analysis, and human-machine collaboration, creating opportunities for upskilling and career advancement.

The Competitive Advantage

Manufacturers who successfully bridge the AI implementation gap today will be positioned to lead tomorrow’s industry transformation. The window of opportunity is now – while 95% are investing, only those with proper integration strategies will realize the full potential.

AI Readiness Assessment

Discover how prepared your manufacturing operation is for AI implementation

1. How would you describe your current data integration?

2. What’s your team’s experience with AI technologies?

3. How do you currently handle production planning and scheduling?

4. What’s your approach to business intelligence and analytics?

5. How would you rate your organization’s change management capabilities?

Your AI Readiness Score

Recommended Next Steps

PentagonIT Can Help

Our integrated approach addresses your specific readiness gaps with proven solutions.

AI Implementation ROI Calculator

Calculate the potential return on investment for your AI manufacturing project

Current State Inputs

Expected Improvements

Annual Savings

Payback Period (months)

3-Year ROI

3-Year Net Benefit

Ready to realize these benefits?

Get Your Free Consultation

Ready to Bridge the AI Implementation Gap?

Don’t be among the 49% who struggle with AI implementation. Join the manufacturers who are successfully transforming their operations with integrated, intelligent systems.

Fast Implementation

50% faster deployment with our proven methodology

Proven Success

100+ successful implementations across 5 countries

End-to-End Support

From assessment to optimization, we’re with you every step