In today’s competitive business landscape, optimizing Make-To-Stock (MTS) planning is crucial for manufacturers looking to stay ahead. MTS is a production strategy where goods are manufactured based on anticipated consumer demand and kept in inventory for quick fulfillment. While this approach ensures product availability and faster response to customer orders, it also presents challenges like excess inventory, stockouts, and inefficient resource utilization.

To maximize efficiency, businesses must balance capacity, inventory, and shelf life. Here’s how companies can leverage modern tools and proven strategies to refine their MTS approach.

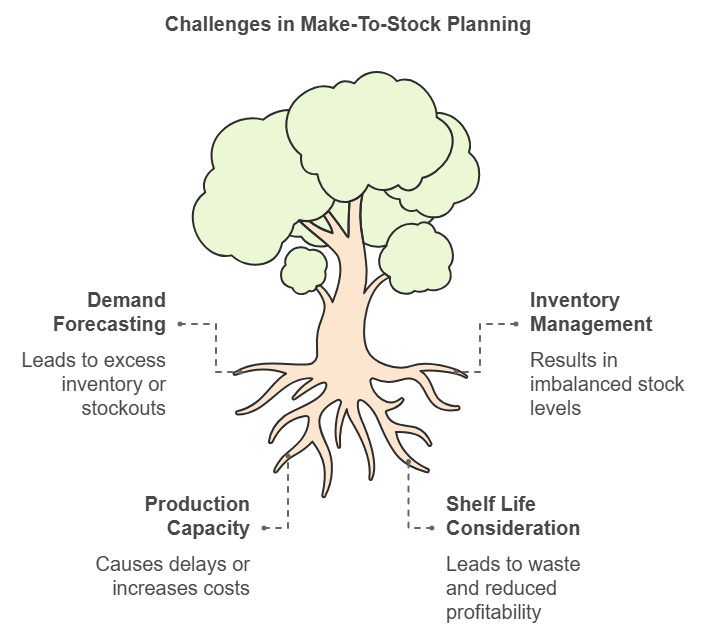

The Key Challenges of MTS Planning

- Forecasting Demand Accurately – One of the most significant challenges is predicting future demand. Overestimating can lead to excess inventory, increasing holding costs and the risk of obsolescence. Underestimating, on the other hand, may result in stockouts and lost sales.

- Managing Inventory Levels – Holding finished goods in anticipation of demand requires robust inventory management systems. Poor tracking can lead to imbalanced stock levels and wasted resources.

- Balancing Production Capacity – Production planning in MTS often involves aligning manufacturing capacity with demand forecasts. Insufficient capacity can cause delays, while overcapacity increases operational costs.

Ensuring Product Shelf Life – For industries like food, pharmaceuticals, or consumer goods, shelf life is critical. Overproduction without considering shelf life can lead to waste, reducing overall profitability.

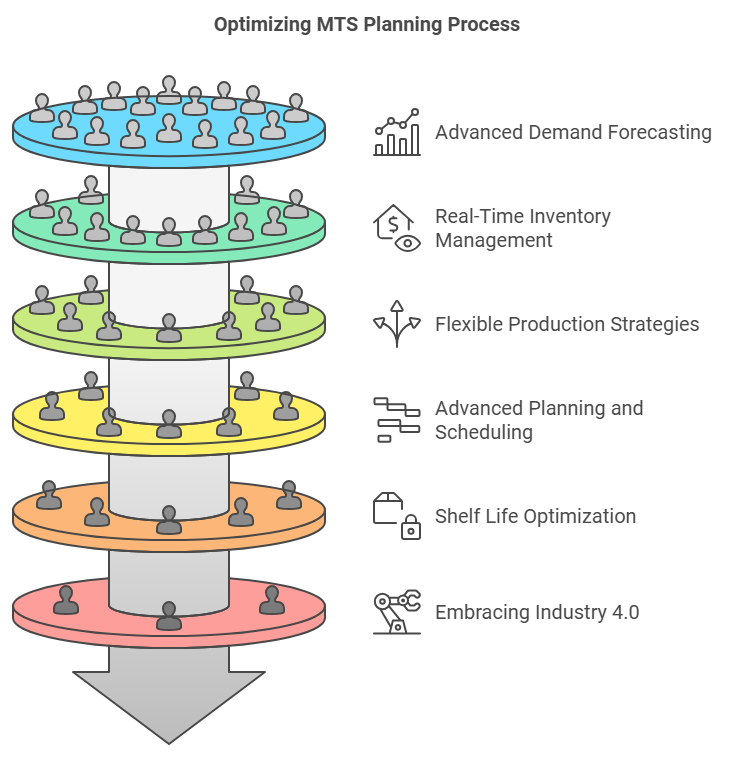

Proven Strategies for Optimizing MTS Planning

To address these challenges and maximize the benefits of MTS, companies can adopt a mix of advanced tools, data-driven methodologies, and cross-functional workflows.

Advanced Demand Forecasting

Incorporate predictive analytics and machine learning tools to analyze historical sales data, market trends, and external factors. Solutions like Qlik Business Intelligence provide actionable insights to create more accurate demand forecasts, reducing the risks of overproduction and stockouts.

Real-Time Inventory Management Systems

Implement an Enterprise Resource Planning (ERP) system to gain a centralized view of inventory levels across locations. Real-time tracking ensures that inventory is optimally allocated and replenished to meet anticipated demand without overstocking.

Flexible Production Strategies

While MTS focuses on anticipated demand, blending it with Make-To-Order (MTO) and Assemble-To-Order (ATO) strategies can enhance flexibility. This hybrid approach allows businesses to maintain a base stock of semi-finished goods and complete them based on specific customer orders.

Advanced Planning and Scheduling (APS) Solutions

Siemens Advanced Planning & Scheduling (APS) tools enable businesses to optimize production workflows, balance capacity, and streamline scheduling. These tools improve resource utilization and minimize lead times, even during peak demand periods.

Shelf Life Optimization Techniques

Implement First-In-First-Out (FIFO) inventory management to ensure older stock is sold first, reducing waste from expired products. Real-time shelf-life tracking systems can also alert teams about approaching expiration dates.

Embracing Industry 4.0 Technologies

Industry 4.0 revolutionizes MTS planning with automation, IoT-enabled inventory systems, and AI-powered forecasting. These technologies enhance visibility, speed up decision-making, and reduce operational risks.

Key Benefits of Optimizing MTS Planning

When companies effectively optimize their MTS planning, they unlock several advantages:

- Enhanced Customer Satisfaction: Quick order fulfillment ensures customers receive their products promptly, boosting loyalty.

- Reduced Costs: Optimized inventory levels lower storage and holding costs, while better forecasts minimize production waste.

- Improved Resource Utilization: Streamlined production planning maximizes manufacturing efficiency, reducing idle time.

- Increased Profitability: Balancing capacity, inventory, and shelf life results in better financial outcomes through lower losses and higher revenue.

Practical Use Cases: MTS Optimization in Action

Consumer Electronics

A leading electronics manufacturer used predictive analytics to forecast seasonal demand. By adjusting production schedules and inventory levels accordingly, the company avoided overproduction and minimized stockouts during the holiday season.

Food Industry

A global food brand implemented IoT-enabled inventory tracking to monitor shelf life in real time. This helped the company reduce waste by 20% and optimize its distribution process.

Retail Sector

A retail giant adopted a hybrid MTS-MTO approach, maintaining a base inventory of popular products while customizing less-demanded items upon order. This improved customer satisfaction and reduced excess inventory.

The Role of Collaborative Workflows

Effective MTS planning relies on collaboration across departments. Cross-functional workflows ensure seamless communication between production, inventory management, and sales teams. Intuitive platforms facilitate real-time updates, enabling faster responses to changes in demand or production schedules.

The Future of MTS Planning: Resilience and Scalability

As markets evolve, MTS strategies must adapt to meet new challenges. Businesses can future-proof their operations by embracing technologies like AI, IoT, and cloud-based solutions. These advancements enable real-time decision-making, greater efficiency, and better scalability.

Conclusion

Optimizing MTS planning is not just about producing goods in advance—it’s about striking the right balance between capacity, inventory, and shelf life. By leveraging advanced tools like Siemens APS, ERP systems, and Industry 4.0 technologies, businesses can reduce waste, improve efficiency, and meet customer demands with precision.

Embrace the future of manufacturing today. Empower your business with intuitive, proven solutions that drive collaboration, efficiency, and growth. Reach out to learn more about transforming your MTS strategy for long-term success.