The Real Cost of Manual Production Planning in Sri Lankan Manufacturing

How Opcenter APS 2504’s Validation Dashboard Could Have Prevented Last Month’s Export Delays

Every Monday Morning, the Same Crisis

The Current Reality

- Monday 6AM: Buyer changes delivery dates on 40,000 units

- Tuesday 8AM: Line 3’s cutting machine breaks down

- Wednesday 10AM: Quality inspector flags dimensional issues

- Thursday 2PM: Still manually reshuffling schedules

- Friday 5PM: Working overtime to find solutions

With Opcenter APS 2504

- Monday 6:05AM: Dashboard shows potential conflicts

- Monday 6:10AM: Click highlights affected operations

- Monday 6:15AM: Automatic rescheduling suggestions

- Monday 6:20AM: Problem solved before shift starts

- Result: 8+ hours saved, zero stress

Why Excel Spreadsheets Fail in Modern Manufacturing

Most Sri Lankan manufacturers still plan production using Excel. Here’s what happens when a rush order arrives:

Production planner manually checks capacity across 8 lines

Discovers Line 5 conflicts with existing orders

Manually reschedules 12 different jobs

Realizes material shortages will delay everything

Buyer threatens order cancellation

Total planning time: 40+ hours

Result: Still not optimized

The Validation Dashboard: Your New Early Warning System

Opcenter APS 2504’s biggest update isn’t another feature. It’s a crisis prevention system.

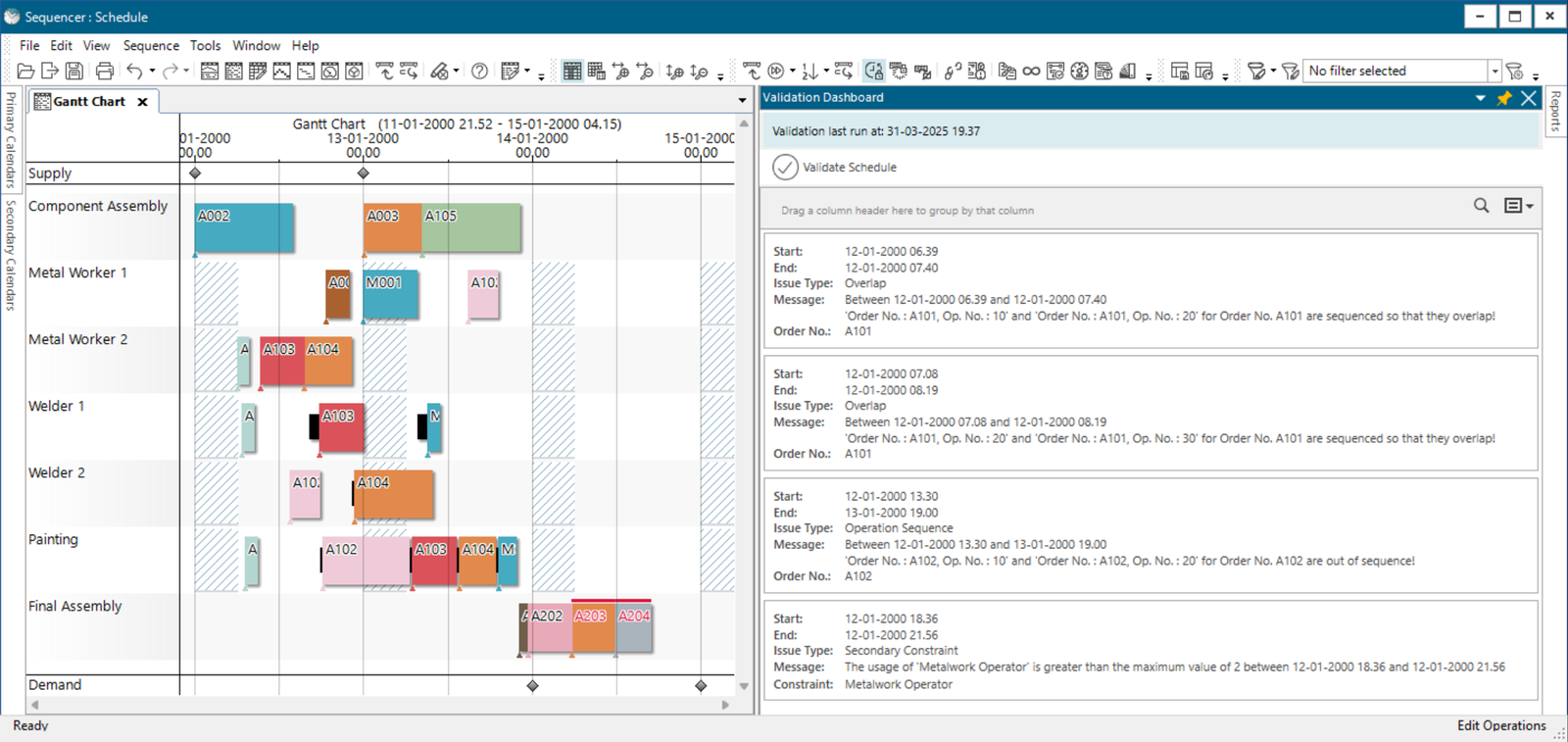

Official Siemens Screenshot: Opcenter APS 2504 Validation Dashboard

Before: Find Problems After They Happen

You discover scheduling conflicts when:

- • Workers stand idle waiting for materials

- • Quality issues surface during final inspection

- • Delivery trucks arrive to half-finished orders

After: See Problems Before They Impact Production

The Validation Dashboard shows you instantly:

- 🔴 Resource Conflicts: “Line 2 scheduled for two jobs simultaneously”

- 🔴 Material Shortages: “Insufficient fabric inventory for Style ABC-2024”

- 🔴 Capacity Overload: “Finishing department exceeds capacity by 23%”

One click. Complete visibility. Zero surprises.

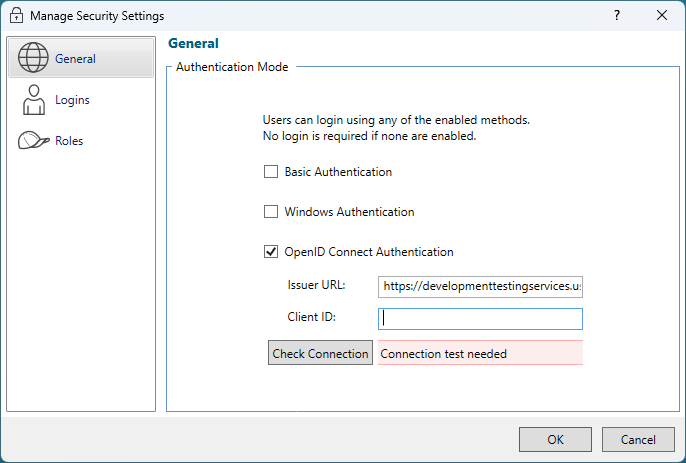

Enterprise-Grade Security for Sri Lankan Operations

OpenID Connect Authentication – Seamless Enterprise Integration

OpenID Connect Authentication

Perfect for large Sri Lankan manufacturers with existing IT infrastructure:

Integration Benefits:

- • Seamless integration with existing Active Directory

- • Single sign-on for all manufacturing systems

- • Centralized user management and role assignment

Compliance Ready:

- • ISO 27001 security standards

- • WRAP compliance for apparel manufacturers

- • Export audit trail requirements

What This Means for Your Daily Operations

Instead of Crisis Management:

Discover yesterday’s quality rejection

Emergency meeting with production team

Start manual rescheduling

Still calculating impact on other orders

Work overtime to find solution

You Get Proactive Control:

Dashboard shows potential quality bottleneck

Click highlights affected operations

Reschedule automatically suggests alternatives

Problem solved before shift starts

Time saved: 8+ hours per incident

Stress reduced: Immeasurable

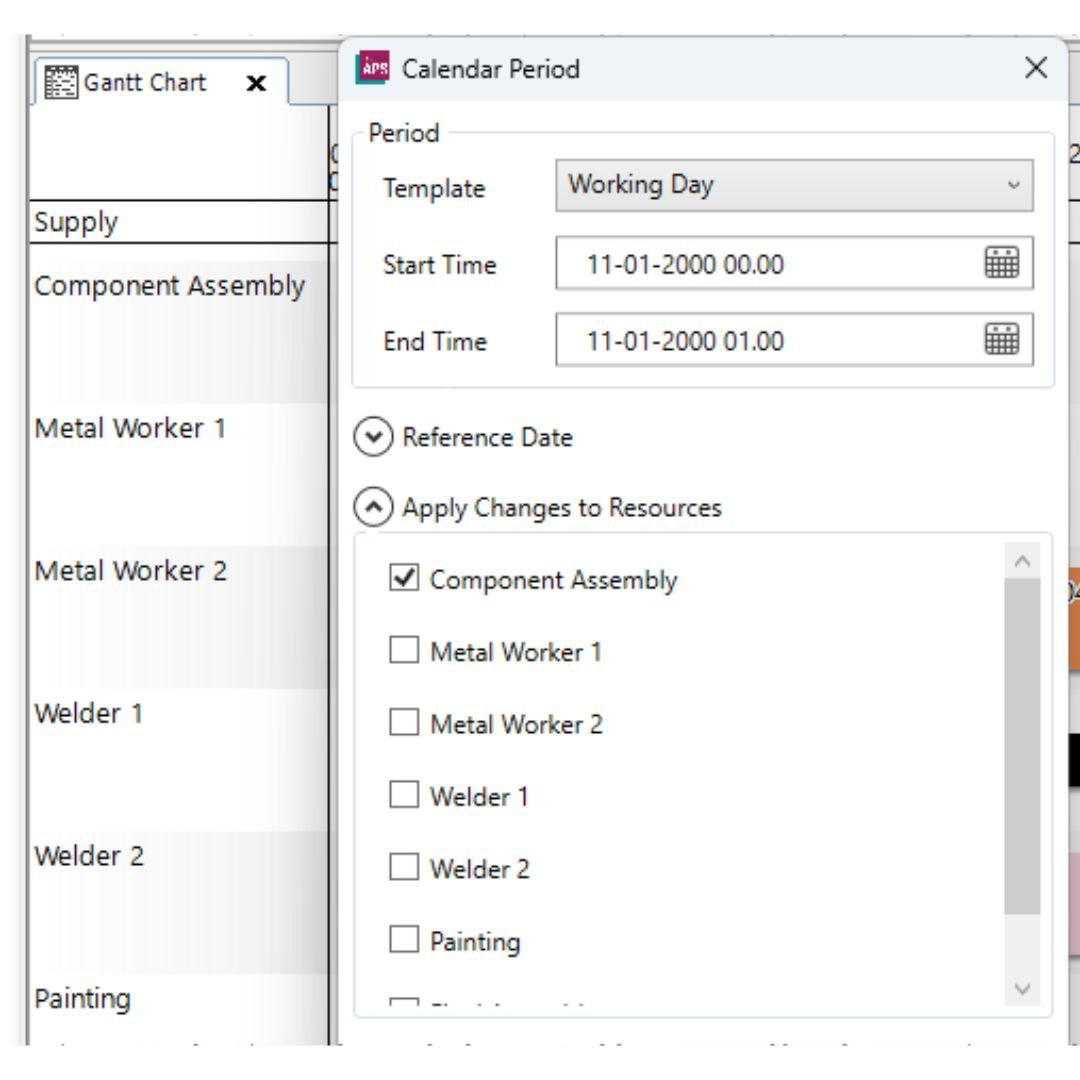

Additional 2504 Updates That Matter

Enhanced Unattended Console

Perfect for 24/7 operations common in Sri Lankan manufacturing:

- • Automated scheduling for continuous production

- • Ideal for apparel factories running multiple shifts

- • Reduces dependency on manual intervention

- • Command-line scheduling accuracy control

Enhanced OData Import

Flexible data integration for complex operations:

- • Filter imports by site or country

- • Multi-language support for local teams

- • Dynamic data tagging and organization

- • Seamless ERP integration

New “Clear All Filters” Feature – Streamlined User Experience

The Real Business Impact

This isn’t about software features. It’s about sleeping better at night.

Validated Schedules

Automatic validation means no constant firefighting

Material Visibility

Conflicts flagged before they happen keeps teams productive

Capacity Planning

Weeks-ahead visibility lets you accept more orders with confidence

Why This Update Matters Now

Sri Lankan manufacturers face three critical pressures:

Buyer Demands

“We need flexibility but zero delays”

Cost Pressure

“Margins are tight, efficiency is everything”

Competition

“Other suppliers promise faster delivery”

Opcenter APS 2504’s Validation Dashboard addresses all three.

Ready to See Your Production Schedule Validated in Real-Time?

Free 30-minute Assessment

We’ll show you exactly which conflicts exist in your current planning process.

Industry-Specific Demo

See the Validation Dashboard working with apparel/food processing workflows.

No Generic Sales Pitch

Just your actual production data, your real bottlenecks, your specific solutions.

Because professional manufacturing demands professional planning tools.