Introduction

- Faster Time-to-Market: Rapid application development leads to quicker deployment of critical business solutions.

- Greater Flexibility: Easily adaptable systems can respond swiftly to evolving business needs.

- Enhanced Collaboration: Teams can work together more effectively using intuitive, user-friendly tools.

1. Streamlining Manufacturing Processes with Low-Code Development

Low-code development plays a crucial role in streamlining manufacturing processes by allowing for fast creation and improvement of software solutions. According to Gartner IT, low-code platforms greatly improve operational efficiency by reducing the time and resources needed for traditional software development. This flexibility enables manufacturers to quickly adapt to market demands and operational issues.

Case Study: Schneider Electric

Schneider Electric provides a compelling example of how low-code can optimize production line monitoring systems. By using low-code platforms, Schneider Electric achieved:

- Real-time Data Visibility: Improved monitoring of production lines, making it possible to quickly identify bottlenecks and inefficiencies.

- Automated Alert Mechanisms: Implementation of automated alerts for maintenance needs, resulting in less downtime and better overall equipment effectiveness (OEE).

These improvements not only made their manufacturing operations more efficient but also led to significant cost savings.

Enhancing Quality Control Measures

Pentagon i Runway offers specialized ERP modules tailored for the Freshbrew™ Tea Industry. With their two decades of expertise in the field, these modules support various aspects of the tea industry, from production to finance and shipping to billing.

By using low-code development, manufacturers can streamline processes and strengthen quality control, leading to improved productivity and operational excellence.

2. Empowering Innovation in Product Development

Rapid Prototyping

Low-code development platforms are instrumental in enabling rapid prototyping, significantly expediting the innovation cycles for new products. According to McKinsey’s research, these platforms can reduce development time by up to 90%, making it faster for manufacturers to move from idea to prototype. This speed allows them to test and improve designs quickly.

Citizen Developers: Fostering a Culture of Innovation

An effective application of low-code technology is seen in the emergence of citizen developers within manufacturing organizations. These non-professional developers can leverage low-code platforms to build proof-of-concept applications quickly. For instance, an engineer on the factory floor might use a low-code tool to develop a custom dashboard that monitors production metrics in real-time. This democratization of software development fosters a culture of innovation, encouraging employees at all levels to contribute creatively to problem-solving and process improvements.

Enhancing Productivity of Professional Developers

Low-code development’s emphasis on visual interfaces and reusable components is a game-changer for professional developers. By handling more routine tasks through low-code solutions, professional developers are freed up to focus on complex and strategic projects. This shift not only boosts productivity but also enhances job satisfaction as developers engage with more challenging and rewarding work.

The integration of low-code platforms like Axpert within custom ERP solutions exemplifies this approach. Axpert enables rapid application development while ensuring robust data modeling and business logic customization, crucial for building sophisticated ERP systems tailored to specific manufacturing needs.

By incorporating these elements, manufacturing companies can harness the full potential of low-code development, driving both efficiency and innovation across their operations.

3. Overcoming Integration Challenges in the ERP Landscape

Legacy Systems Integration

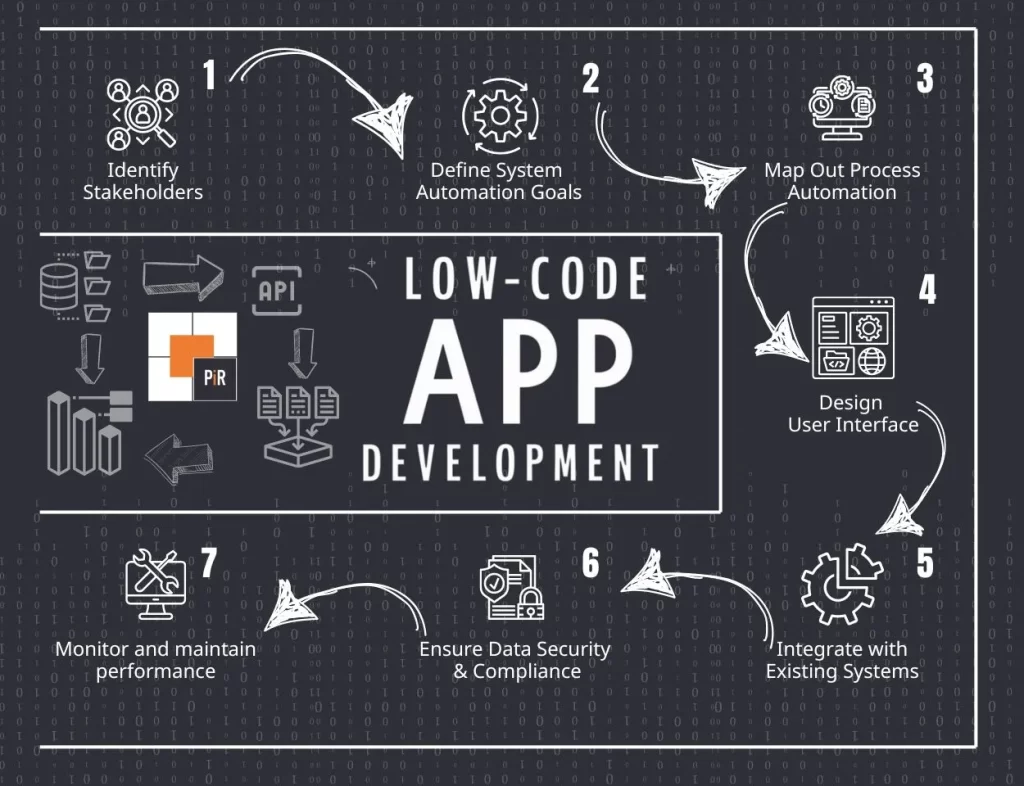

Integrating custom ERP solutions with existing legacy systems is made easier with low-code development. This is done using built-in API capabilities that allow smooth data exchange between different systems. With APIs, low-code platforms can connect with older technologies, ensuring that important data flows seamlessly across various applications.

Ensuring Data Consistency and Integrity

Maintaining data consistency and integrity during integration processes is crucial for the success of any ERP system. Best practices in low-code development emphasize strict data validation protocols and automated error-checking mechanisms. These features help prevent discrepancies that could lead to operational inefficiencies or decision-making errors.

Key strategies include:

- Using data modeling tools within low-code platforms to accurately map out data structures.

- Implementing real-time synchronization methods to keep datasets consistent across all integrated systems.

- Employing strong security measures to protect sensitive information during data transfers.

For example, Pentagon i Runway's Advanced Planning & Scheduling solutions demonstrate how automation and integration can streamline manufacturing processes by providing real-time data insights and optimizing production schedules.

Additionally, organizations operating in the corrugated box market can leverage Pentagon i Runway's comprehensive report which covers key data and analysis on market size, growth, key players, dynamics, challenges, and opportunities for growth. Armed with this information, businesses can make informed decisions to stay ahead of the curve.

By addressing these integration challenges, manufacturers can achieve a cohesive and efficient ERP environment that supports their digital transformation goals.

Choosing the Right Low-Code Platform for Your Manufacturing Needs

Understanding the difference between low-code and no-code platforms is crucial. Low-code platforms provide a more flexible way to develop applications, catering to both experienced developers and non-technical users. These platforms have visual tools for creating applications while still allowing for custom code when needed. No-code platforms, on the other hand, are mainly designed for business users with no coding experience, which can be a limitation in complex manufacturing settings.

Why Low-Code is More Suitable for Manufacturing

Manufacturing processes often involve complex workflows and require strong ERP-specific features. Low-code platforms are generally better suited because they can:

- Support Complex Logic: Unlike no-code solutions, low-code platforms make it easier to customize sophisticated business rules.

- Seamlessly Integrate: They have built-in API capabilities that make it simpler to connect custom ERP solutions with existing systems.

- Scale Up: Low-code platforms can handle the growing needs of large manufacturing operations.

Evaluating Low-Code Vendors

When selecting a low-code vendor, consider these key features:

- Data Modeling: Make sure the platform supports comprehensive data modeling to handle complex manufacturing data structures.

- Business Logic Customization: Look for powerful tools that allow detailed customization of business processes.

- User Interface Flexibility: The platform should offer flexibility in designing user interfaces tailored to specific operational requirements.

- Integration Capabilities: Assess how well the platform integrates with older systems and other enterprise applications.

For example, Pentagon i Runway’s Process Manufacturing ERP uses low-code principles to streamline production workflows. This enables manufacturers to create goods by combining raw materials, ingredients, or substances through a series of chemical processes. Similarly, their specialized PestOps™ Pest Management ERP demonstrates how industry-specific ERPs can benefit from low-code platforms by providing customized solutions without sacrificing complexity or performance.

Incorporating these considerations will help manufacturing companies choose a low-code platform that not only meets their immediate needs but also scales with their changing requirements.

The Low-Code Development Landscape in Sri Lanka

Sri Lanka’s low-code development market is rapidly evolving, marked by the emergence of homegrown platforms like Quixy. These platforms are gaining traction, offering robust solutions tailored to the unique needs of the local manufacturing sector, including those involved in printing and packaging.

1. Emergence of Homegrown Platforms

Quixy has positioned itself as a significant player in the realm of low-code development within Sri Lanka. It provides a versatile platform that enables rapid application development, which is crucial for manufacturing companies aiming to stay competitive.

2. Skilled Workforce

The availability of a skilled workforce familiar with low-code technologies is a notable advantage for Sri Lankan manufacturing companies. This talent pool facilitates quicker adoption and integration of low-code solutions, ensuring that businesses can leverage these technologies effectively.

For manufacturers involved in complex sectors such as printing and packaging, adopting low-code platforms like Quixy can streamline operations by simplifying custom ERP implementation and optimizing workflow processes.

Additionally, leveraging advanced data visualization tools available through these platforms can provide meaningful insights, enabling better decision-making and operational efficiency.

The combination of local expertise and innovative low-code solutions positions Sri Lanka as a promising hub for digital transformation in the manufacturing industry.

4. Ensuring Long-Term Success with Low-Code and ERP Integration

Establishing a Governance Framework

To ensure long-term success with low-code development practices, especially when integrating custom ERP solutions, a robust governance framework is crucial. This framework should encompass:

- Standardized Development Protocols: Consistent coding standards, naming conventions, and documentation practices.

- Quality Assurance Mechanisms: Regular code reviews, automated testing, and continuous integration pipelines to ensure that all applications meet high-quality standards.

- Training and Support: Providing ongoing training for both professional developers and citizen developers to keep up with the latest best practices and technological advancements.

Scalability Considerations

Scalability plays a vital role in the effectiveness of low-code solutions as manufacturing operations grow or adapt over time. Key considerations include:

- Modular Architecture: Designing applications with a modular approach allows individual components to be upgraded or replaced without affecting the entire system.

- API Capabilities: Leveraging built-in API capabilities of low-code platforms to facilitate seamless integration with other enterprise systems, ensuring data consistency and integrity.

- Performance Monitoring: Continuous monitoring of application performance to identify bottlenecks and optimize resource usage.

Implementing these strategies ensures that as manufacturing operations expand, low-code ERP solutions can scale accordingly. To gain more insights on scalable digital solutions, explore our Agile Labs partnership which offers leading technology solutions to unlock the full potential of your business.

In addition to these strategies, advanced planning and scheduling tools like Siemens Opcenter APS can further enhance the efficiency and scalability of your manufacturing processes.

By establishing a strong governance framework and focusing on scalability, manufacturers can ensure long-term success with their low-code ERP integrations.

The Future of Manufacturing Powered by Custom ERP Solutions and Low-Code Development

Custom ERP solutions combined with low-code development are set to revolutionize the manufacturing industry. This synergy propels digital transformation by integrating emerging technologies like AI and IoT into everyday operations.

Intelligent Automation and Predictive Maintenance

- AI Integration: Leveraging AI algorithms within custom ERP systems can enable predictive maintenance, reducing downtime and extending machinery life.

- IoT Connectivity: IoT devices provide real-time data that feeds into ERP systems, enhancing decision-making processes. For example, sensors on production lines can alert managers to potential issues before they escalate.

Enhanced Flexibility and Scalability

- Adaptive Workflows: Low-code platforms allow manufacturers to quickly adapt their ERP workflows in response to changing market demands or operational needs.

- Scalable Solutions: As manufacturing operations grow, low-code solutions ensure that the ERP system scales seamlessly without significant overhauls.

Real-Time Analytics for Proactive Decision-Making

- Data-Driven Insights: Custom ERPs integrated with advanced analytics tools like Qlik offer actionable insights, helping manufacturers optimize processes and resource allocation.

Exploring these advancements highlights how manufacturing companies can achieve higher efficiency and innovation. For instance, Pentagon i Runway’s Glove ERP, which provides the ability to have a highly efficient workflow, showcases how tailored solutions streamline industry-specific activities. Similarly, Pentagon i Runway’s Poultry and Meat Processing ERP demonstrates how customized ERPs can optimize complex processes in the poultry industry, meeting the ever-growing demand for high-quality protein sources.

Manufacturers looking to embrace this future should consider the transformative potential of combining custom ERPs with low-code development, ensuring a robust and adaptable digital foundation.

Conclusion

Embracing the opportunities presented by custom ERP solutions and the advantages of low-code development in manufacturing is crucial for staying competitive in the digital age. The insights shared throughout this article highlight the potential for streamlined processes, accelerated innovation, and seamless integration that these technologies offer.

Manufacturing executives are encouraged to explore how tailored ERP solutions powered by low-code development can transform their operations. Leveraging these advanced tools can lead to faster time-to-market, increased operational efficiency, and a more agile response to changing business needs.

Pentagon i Runway stands ready to support your journey toward digital excellence. With expertise in delivering comprehensive ERP solutions and a commitment to leveraging low-code development strategies, Pentagon i Runway can help your organization achieve its digital transformation goals.

Explore our specialized ERP offerings in various industries:

- Agriculture and Plantation: In the dynamic landscape of sugar plantation management, efficiency, precision, and seamless workflows stand as essential pillars. Our bespoke ERP solution is specifically designed to address these challenges.

- Textile: Once a handicraft industry, textile production is now an engineering activity that uses various technologies and processes to design and develop textiles. Our tailor-made ERP solution can optimize this complex process while ensuring efficient resource utilization.

Take the next step towards elevating your manufacturing capabilities with Pentagon i Runway’s innovative solutions.

FAQs

Custom ERP solutions play a crucial role in improving efficiency in manufacturing by streamlining processes, enhancing quality control measures, empowering innovation in product development, and overcoming integration challenges in the ERP landscape.

Low-code development plays a crucial role in streamlining manufacturing processes by enabling rapid prototyping, fostering a culture of innovation among citizen developers, and enhancing the productivity of professional developers through visual interfaces and reusable components.

Low-code applications are especially useful in enhancing quality control measures by providing tools for ensuring data consistency and integrity during integration, as well as offering the ability to choose the right low-code platform for manufacturing needs.

Low-code development platforms are instrumental in enabling rapid prototyping, fostering a culture of innovation among citizen developers, and enhancing the productivity of professional developers through visual interfaces and reusable components.

With low-code development, challenges such as legacy systems integration, ensuring data consistency and integrity during integration, and choosing the right low-code platform for manufacturing needs can be effectively addressed.

Long-term success with low-code development practices and ERP integration can be ensured by establishing a governance framework and considering scalability considerations to maintain effectiveness.